Natural gas is also a versatile fuel that can be used in a variety of industries

In conclusion, natural gas filters play a vital role in the production and utilization of natural gas, ensuring that it remains a viable and cleaner energy source. With various filtration technologies available, the industry can effectively address the challenges posed by impurities and enhance the environmental benefits of natural gas. As the world shifts toward cleaner energy solutions, investing in advanced filtration technologies will be key in maximizing the potential of natural gas in a sustainable energy future.

Most modern pressure reducers are equipped with a diaphragm that responds to changes in pressure. As the downstream pressure varies, the diaphragm moves accordingly, opening or closing a valve to maintain the predetermined pressure. This dynamic adjustment process ensures that fluctuations in demand or supply do not affect the end user.

There are several types of relief valves, each designed for specific applications

- Residential Appliances Stoves, heaters, and water heaters commonly utilize gas pressure regulators to ensure proper functioning.

Moreover, the continuous evolution of pressure control technologies drives innovation in sectors like renewable energy. As industries shift towards greener practices, advanced pressure management systems are becoming crucial in the efficient operation of processes like carbon capture and storage. By maintaining optimal pressure levels in these systems, companies can enhance their sustainability efforts while complying with environmental regulations.

Understanding Gas Pressure Vessels Importance and Applications

Understanding Gas Pressure Regulator Valves

The implementation of gas filtration systems provides numerous benefits for industries, including

Decompression skids are typically equipped with several components, including pressure regulators, heaters, and safety valves. These elements work together to gradually reduce the pressure of the extracted hydrocarbons to a safe level. The skids are designed to accommodate various fluid types and conditions, making them versatile tools suitable for different operational requirements.

At its core, a gas coalescer filter employs the principle of coalescence to remove contaminants from gas. When a gas stream flows through the filter, it passes through layers of specialized media that are engineered to promote the agglomeration of fine liquid droplets suspended in the gas.

Pressure reducing valves are found in various industries, including water distribution, oil and gas, HVAC systems, and manufacturing. In municipal water systems, for instance, PRVs are critical in reducing the high pressure from water mains to a safe level for residential and commercial use. This not only protects plumbing fixtures but also conserves water by preventing leaks and excessive flow.

Given the potential hazards associated with storing gases at high pressures, safety is a top priority in the design and operation of gas pressure vessels. Engineers must adhere to strict industry regulations, such as those set forth by the American Society of Mechanical Engineers (ASME) and other relevant bodies. These regulations cover everything from material selection to testing procedures, ensuring that vessels are built to last and minimize the risk of catastrophic failure.

Additionally, data analytics is playing a crucial role in predicting maintenance needs and improving efficiency. By analyzing consumption patterns and system performance, gas companies can make informed decisions that enhance reliability and reduce operational costs.

The Concept of المثبت (Al-Muthbit)

The primary function of a safety pressure relief valve is to sense the internal pressure and open when it reaches a set threshold, allowing the excess pressure to escape. This process helps in preventing explosions, equipment damage, and potential injuries to workers present in the vicinity. Once the pressure drops back to a safe level, the valve closes automatically, resuming normal operations.

Applications and Importance

Shut-off valves find applications in a wide variety of industries, including water and wastewater management, oil and gas, chemical processing, and pharmaceuticals. In residential settings, they are commonly used for controlling the water supply to appliances such as dishwashers and washing machines.

A natural gas pressure regulator is a device that reduces and stabilizes the pressure of natural gas before it enters a pipeline or a gas appliance. Without these regulators, the high pressure from gas supply lines could cause damage to appliances or create unsafe conditions. Regulators are essential in both residential and commercial settings, ensuring that the gas delivered is at the appropriate pressure for various applications.

In industrial settings, coalescing filters are used in hydraulic systems and other machinery where cleanliness of fluids is paramount. For example, in manufacturing processes, maintaining the purity of lubricants can extend machinery life and enhance operational efficiency. Additionally, automotive fuel systems commonly incorporate coalescing filters to safeguard engines from contaminants, thus improving reliability and fuel efficiency.

The importance of natural gas filtration cannot be overstated. Impurities in natural gas can lead to a range of operational issues, including pipeline corrosion, reduced efficiency of combustion systems, and increased emissions of harmful pollutants. For instance, the presence of water can cause the formation of hydrates, which can block pipelines, while hydrogen sulfide is a toxic compound that poses severe health risks. Furthermore, contaminants can affect the performance of gas appliances and engines, leading to costly repairs and inefficiencies. Thus, effective filtration is essential not only for regulatory compliance but also for the longevity and reliability of gas infrastructure.

Gas regulators are essential devices used in various industries and applications to control the pressure of gas delivered from a supply source to the end-user. They play a critical role in ensuring safe and efficient gas usage in residential, commercial, and industrial settings. This article will delve into the function and importance of gas regulators, highlighting their components and applications.

The Organization of Natural Gas A Vital Energy Resource

Gas pressure regulators are used across many sectors, including

In addition to protecting physical assets, PRVs are crucial for ensuring the safety of personnel working in potentially hazardous environments. The consequences of equipment failure can be dire, not only posing risks to human life but also leading to environmental disasters and significant financial losses. As such, PRVs are often mandated by safety regulations and standards in various industries, including petrochemical, pharmaceutical, and food processing.

Because of the inherent risks associated with pressure vessels, they are subject to stringent regulations and industry standards. Organizations such as the American Society of Mechanical Engineers (ASME) set guidelines for the design, construction, and maintenance of pressure vessels. Compliance with these standards not only ensures safety but also enhances the reliability and efficiency of the equipment.

1. Safety High pressure can lead to catastrophic failures, including bursts and leaks. A PRV acts as a safety measure by limiting the maximum pressure that can be exerted within a system, protecting both equipment and personnel.

- Safety The primary purpose of gas safety valves is to protect people and equipment from the dangers associated with over-pressurized systems. By preventing explosions and equipment failures, these valves help safeguard lives and property.

In the energy sector, they are crucial components in the storage of compressed natural gas (CNG) for vehicles and as part of renewable energy systems, storing energy produced by wind or solar power In the energy sector, they are crucial components in the storage of compressed natural gas (CNG) for vehicles and as part of renewable energy systems, storing energy produced by wind or solar power

In the energy sector, they are crucial components in the storage of compressed natural gas (CNG) for vehicles and as part of renewable energy systems, storing energy produced by wind or solar power In the energy sector, they are crucial components in the storage of compressed natural gas (CNG) for vehicles and as part of renewable energy systems, storing energy produced by wind or solar power gas pressure vessel.

gas pressure vessel.What is a Gas Regulator?

Shut-off valves come in several types, with each designed for distinct applications. The most common types include

Heat exchangers are vital components in many industrial processes, playing a crucial role in energy efficiency and temperature regulation across various applications. From power plants to chemical processing, the effective transfer of heat between fluids is essential for optimizing performance and reducing operational costs.

The origins of wrought iron are traced back to ancient civilizations, where blacksmiths expertly shaped iron into various tools and decorative items. The word wrought comes from the Old English wroughten, which means to work or shape through labor. Unlike cast iron, which is brittle and can crumble under pressure, wrought iron is malleable and can be manipulated at high temperatures to create intricate shapes and forms.

The group comprehensively implemented ISO9001:2008 quality management system, passed ISO 9001, ISO 14000, ISO18000 certification, and energy conservation certification, and obtained honors such as Guangxi Famous Brand and High and New Tech Enterprise.

When looking for wrought iron welding near you, it is important to find a reputable and experienced welding service. This is crucial to ensure that the welding work is done correctly and effectively, as poorly done welding can compromise the integrity and strength of the metal.

1. 15 days production;

2. If opening new mould, 20 days.

metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility.

metal storage box with lock. Many models come with handles or wheels, making it easy to move the box from one location to another. This is especially useful if you need to transport your valuables to a different place, such as a safety deposit box at a bank or a safe deposit box rental facility.One of the biggest benefits of a large metal lockable box is its durability and strength. Made of tough metal materials such as steel or aluminum, these boxes are built to withstand impact and resist tampering. This means that even in the event of a break-in or natural disaster, your items will remain safe and secure inside the box.

Even little items like the screws and bolts used can be something that makes installation a pain or detracts from the look of the fence. Make sure the hardware is color matched to your pieces and uses a stronger hex-head on the bolts that allow use of a socket. Phillips head style screws can often strip easily and make installation a pain.

Aluminium window extrusion profiles offer architects and designers unparalleled flexibility when it comes to creating unique and visually appealing building facades. Unlike other materials, aluminium can be easily extruded into various profiles and shapes, allowing for endless customization possibilities. Whether you prefer sleek and minimalist designs or intricate detailing, aluminium window extrusion profiles can be tailored to meet your specific aesthetic requirements. Furthermore, aluminium's inherent strength allows for larger glass surfaces, creating a seamless and modern look while maximizing natural light.

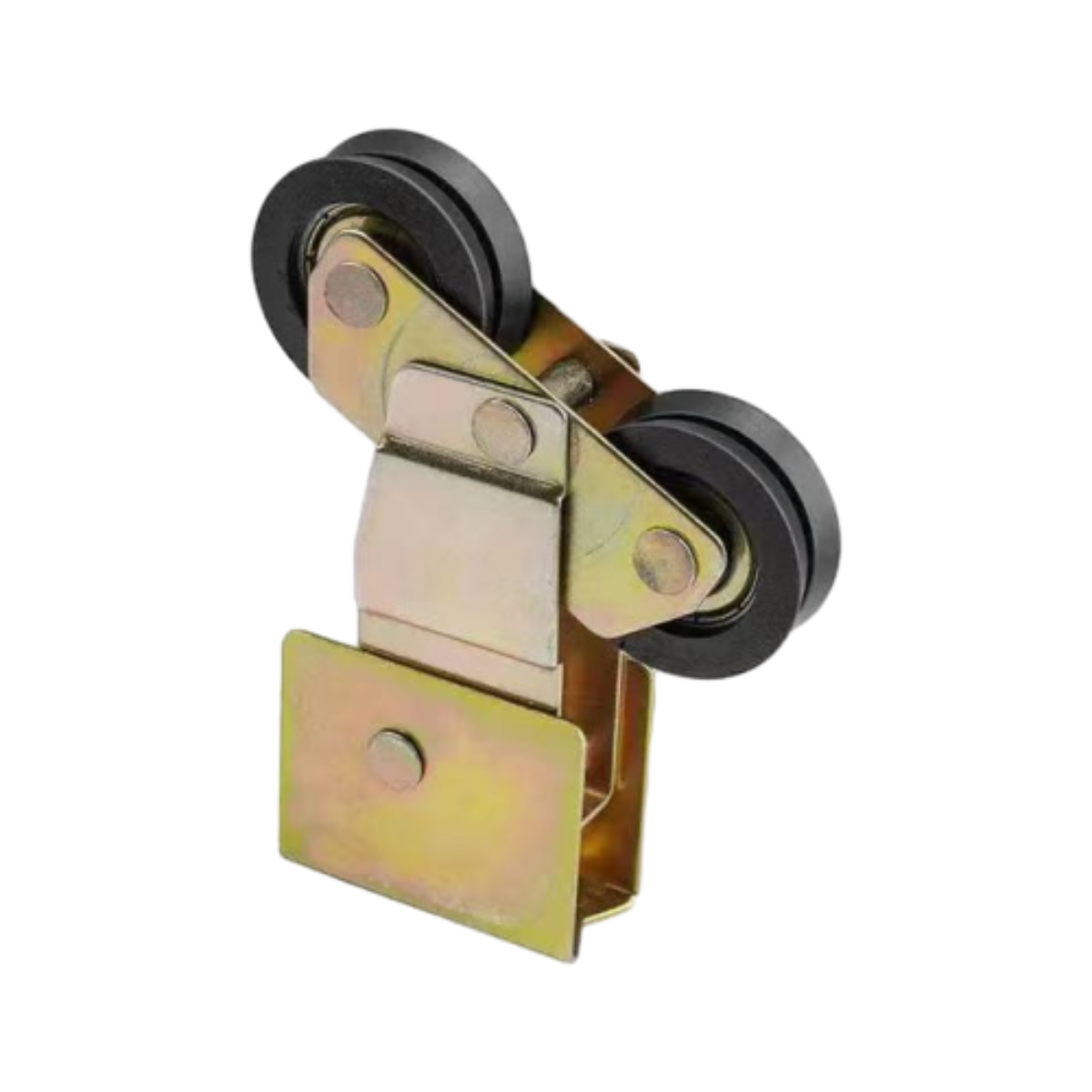

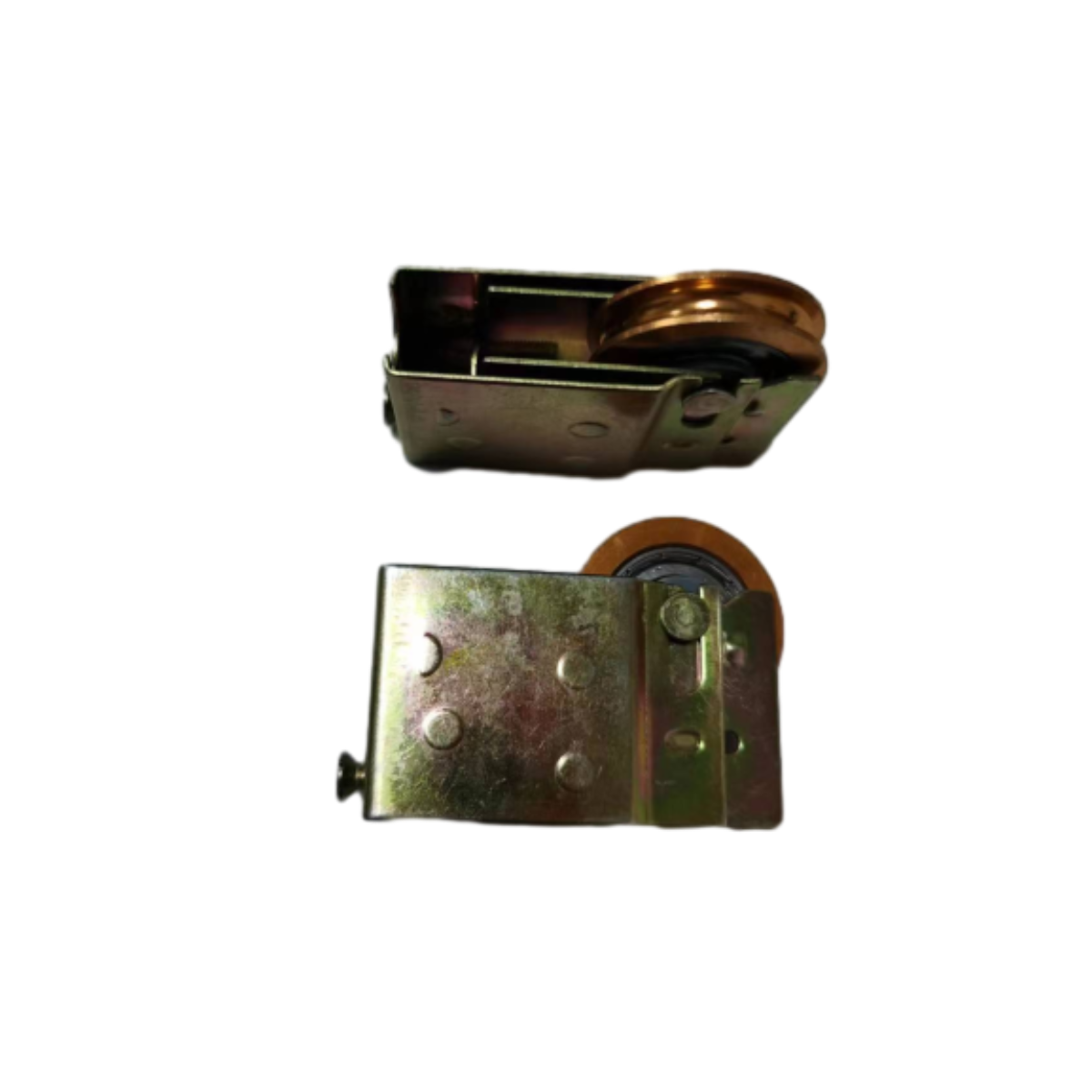

There are several tips for you in selecting a high-quality aluminium window. First and foremost, the thickness of aluminium profiles of the aluminium windows should not be less than 1.2mm. Tempered glass or laminated glass are also better than float glass. If you consider the safety and durability of the windows, choose stainless steel hardware accessories (such as screws, hinges, handles, etc.) It is also advisable to choose pulley that is made of POM material. These products have higher strength and abrasion resistance. They are smooth during operation and not easily damaged.

5. Check for Level Use a level to ensure that the door is aligned correctly. An unlevel door can cause excessive wear on the rollers and the track, leading to future misalignments. If necessary, make further adjustments to ensure the door is perfectly level.

This may seem like a small and unimportant item, but shortcuts here can make a nice iron fence or gate look cheap. Pay attention to the smaller elements like the brackets that connect the iron fence to the posts, the post caps and decorative finials on top of the pickets.

The charm of decorative wrought iron pieces lies in their rich history, exquisite craftsmanship, and timeless appeal. They serve as a testament to the skill and artistry of the blacksmith, transforming functional items into beautiful works of art. As trends come and go, wrought iron remains a staple in design, celebrated for its durability and aesthetic versatility. Whether enhancing a garden, adding elegance to an entryway, or creating a unique focal point in interior decor, decorative wrought iron pieces continue to capture the attention and admiration of many. Embracing wrought iron in design not only pays homage to centuries of craftsmanship but also enriches our surroundings with beauty and character.

As such, it makes the material hardy and thus can withstand different harsh environmental and mechanical conditions.

To prolong the life of aluminum sliding door rollers and ensure optimal performance, regular maintenance is essential. Here are some best practices